Products

- Elastomer-metal vibration isolator

- Rubber-metal vibration isolator (support)

- Rubber-metal vibration isolator (foot pad)

- Rubber vibration isolator- S.C

- Rubber vibtation isolator - EV

- Rubber vibration isolator - PA

- Rubber vibration isolator - PA

- Rubber vibraton isolator- &quo

- Rubber vibration isolator- CUP

- Rubber vibration isolator -STA

- Rubber vibration isolator bear

- Engine unit vibration isolator

- Rubber vibration isolator -MIN

- Rubber vibration isolator - BE

- Rubber vibration isolator- POL

- Rubber-metal vibration isolator (suspension)

- Rubber-metal vibration isolator (military)

- Rubber vibration isolator- ST

- Rubber vibration isolator- VI

- Rubber vibration isolator- VI

- Rubber vibration isolator- &qu

- Rubber vibration isolator - GB

- Rubber vibration isolator - VI

- Rubber vibration isolator - VI

- Rubber vibration isolator- VIB

- Rubber vibration isolator- VII

- Rubber vibration isolator - lo

- Rubber vibration isolator - VI

- Silicone damping vibration isolator

- Elastomer spring

- Mechanical equipment vibration isolation pad foot

- Steel spring assembly vibration isolator

- Small steel spring set vibration isolator

- Large steel spring set vibration isolator

- S-WLP steel spring vibration i

- S-ULP steel spring vibration i

- S-ULP steel spring vibration i

- S-WP (R) steel spring vibratio

- S-WP steel spring vibration is

- S-WPV steel spring vibration i

- S-WPV (R) steel spring vibrati

- S-WLP steel spring vibration i

- S-WLP steel spring vibration i

- S-WLP steel spring vibration i

- S-WLP steel spring vibration i

- S-WLP steel spring vibration i

- Steel spring-viscous damping vibration isolator

- Steel spring vibration isolator

- Damping vibration isolator

- Air spring vibration isolator

- Metal wire, vibration isolator

- Steel wire rope vibration isolator

- Metal wire vibration isolator

- Metal wire vibration isolators

- Metal wire vibration isolator

- Metal wire vibration isolators

- Metal wire vibration isolator

- Metal wire vibration isolator

- Metal wire vibration isolator

- Metal wire vibration isolator-

- Metal wire vibration isolator

- Metal wire vibration isolator

- Metal wire vibration isolator

- Wire rope vibration isolator -

- Metal wire vibration isolator

- HVAC vibration isolator

- Hanging vibration isolator

- Floating floor vibration isolator

- HVAC vibration isolator

- DZE 3D damping vibration isola

- MSN-D damping vibration isolat

- COMPACT damping vibration isol

- DZE damping vibration isolator

- DZE-MINI damping vibration iso

- DZE-BL damping vibration isola

- SE light series vibration isol

- SE-DE series traction machine

- ENI leveling vibration-isolati

- CGR vibration isolator

- EW vibration isolator gasket

- TR Transformer vibration isola

- PBE vibration isolator pad

- SE Pro series vibration isolat

- Active vibration isolation system

- Anti-vibration base

- Polyurethane elastomer vibration isolation material

- RELOMER SRG60 vibration isolat

- RELOMER SRG35 vibration isolat

- RELOMER SRG14 vibration isolat

- RELOMER SRG08 vibration isolat

- ACOUSTIC FLOOR MAT 35

- ACOUSTIC FLOOR MAT 33

- ACOUSTIC FLOOR MAT 29

- ROLL acoustic floor mat

- Sylocraft vibration isolation

- Sylodyn high dynamic vibration

- Sylomer elastic vibration isol

- Sylodamp damping and vibration

首页 > Products > Elastomer-metal vibration isolator > Coupling vibration isolator

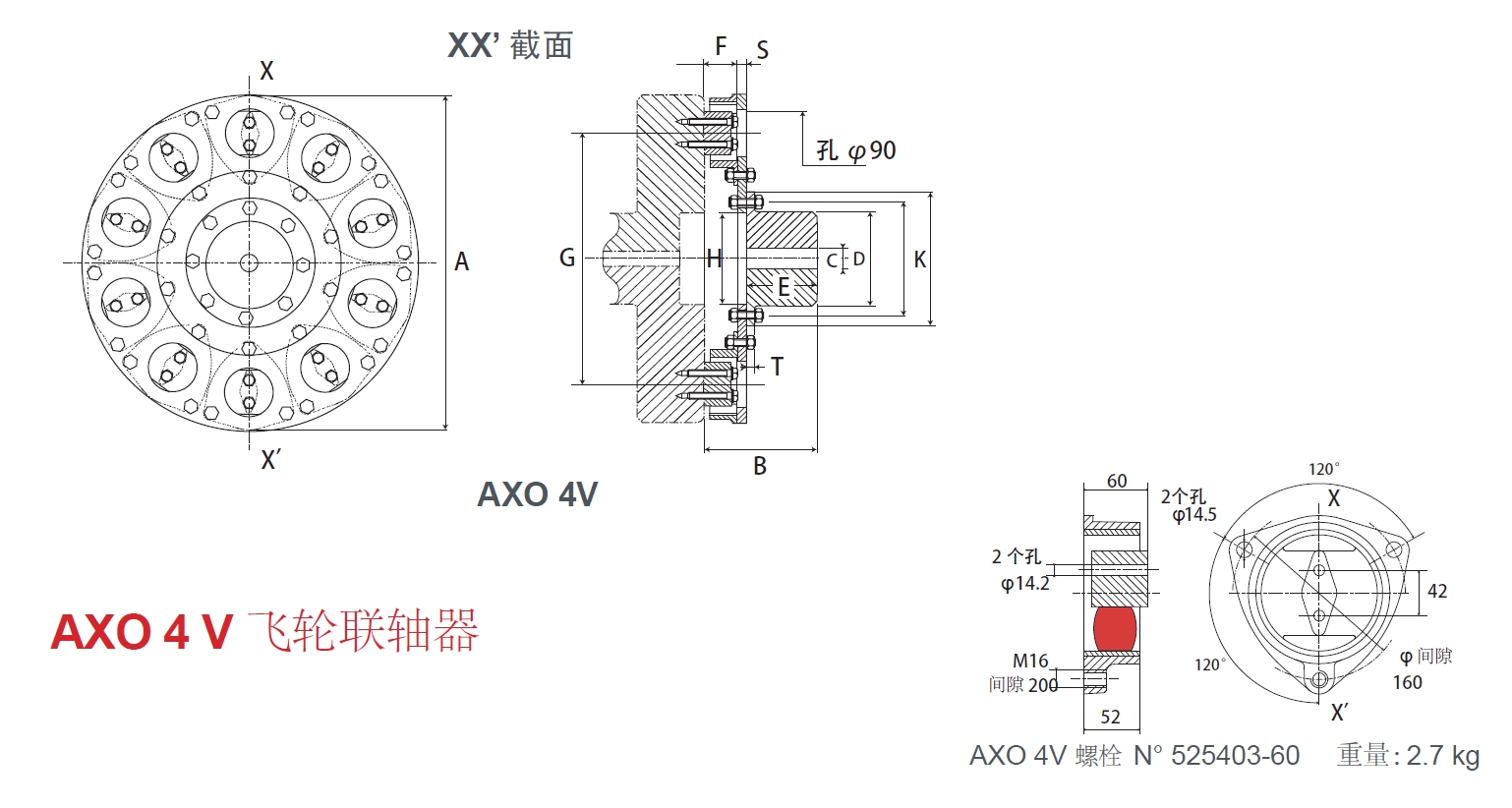

Elastic coupling - Axoflex

-

Elastic coupling - Axoflex Overview -

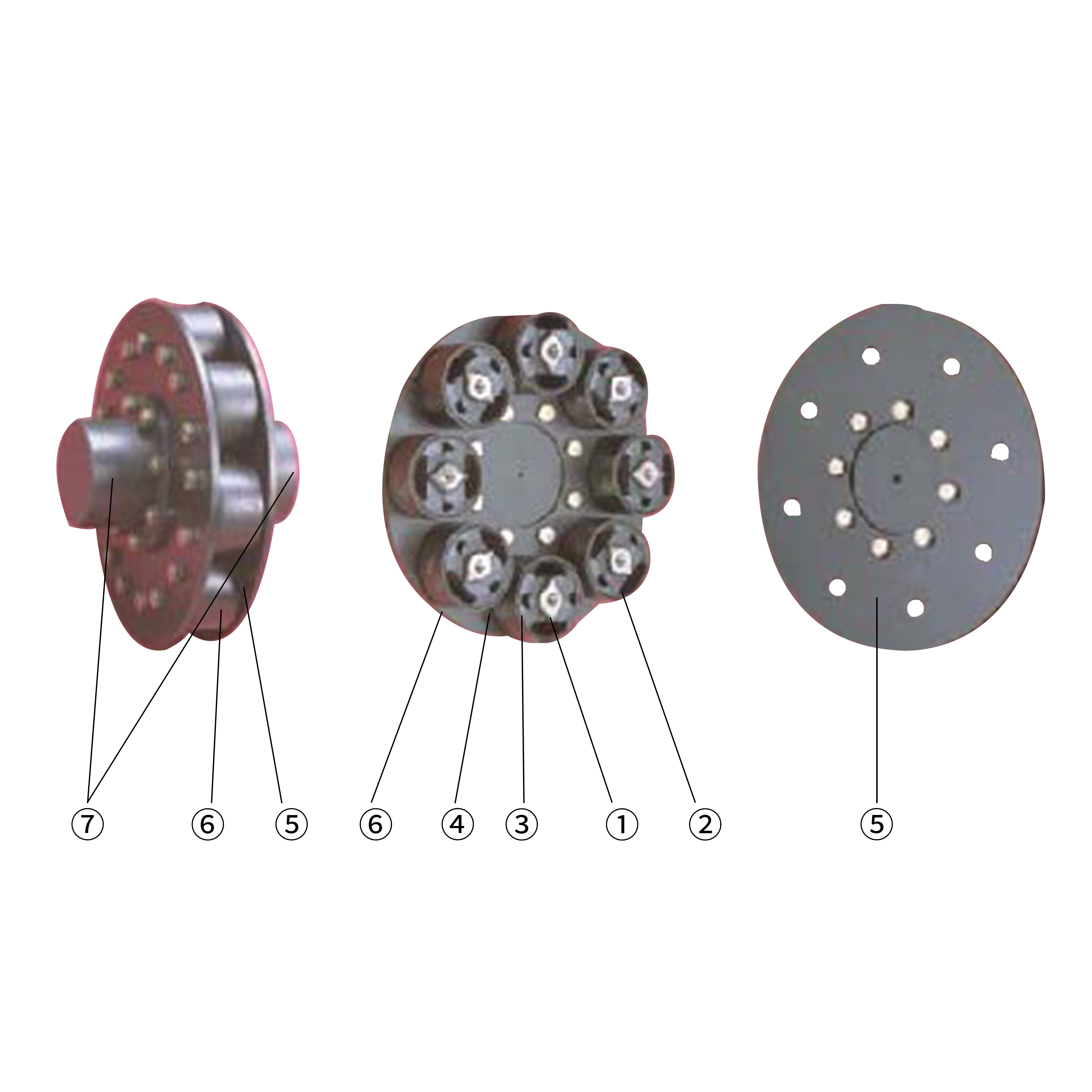

➤Flexible element comprising a variable number of flexible bushes,depending on the torque to betransmitted. Inner with tapped or smooth holes (normal mounting or on flywheel).

Precompressed natural rubber bonded to inner and to outer the half-cylinders .

Half-cylinders bonded to the rubber.

Outer housing ensuring precompression of rubber by exerting pressure on the

half-cylinders .

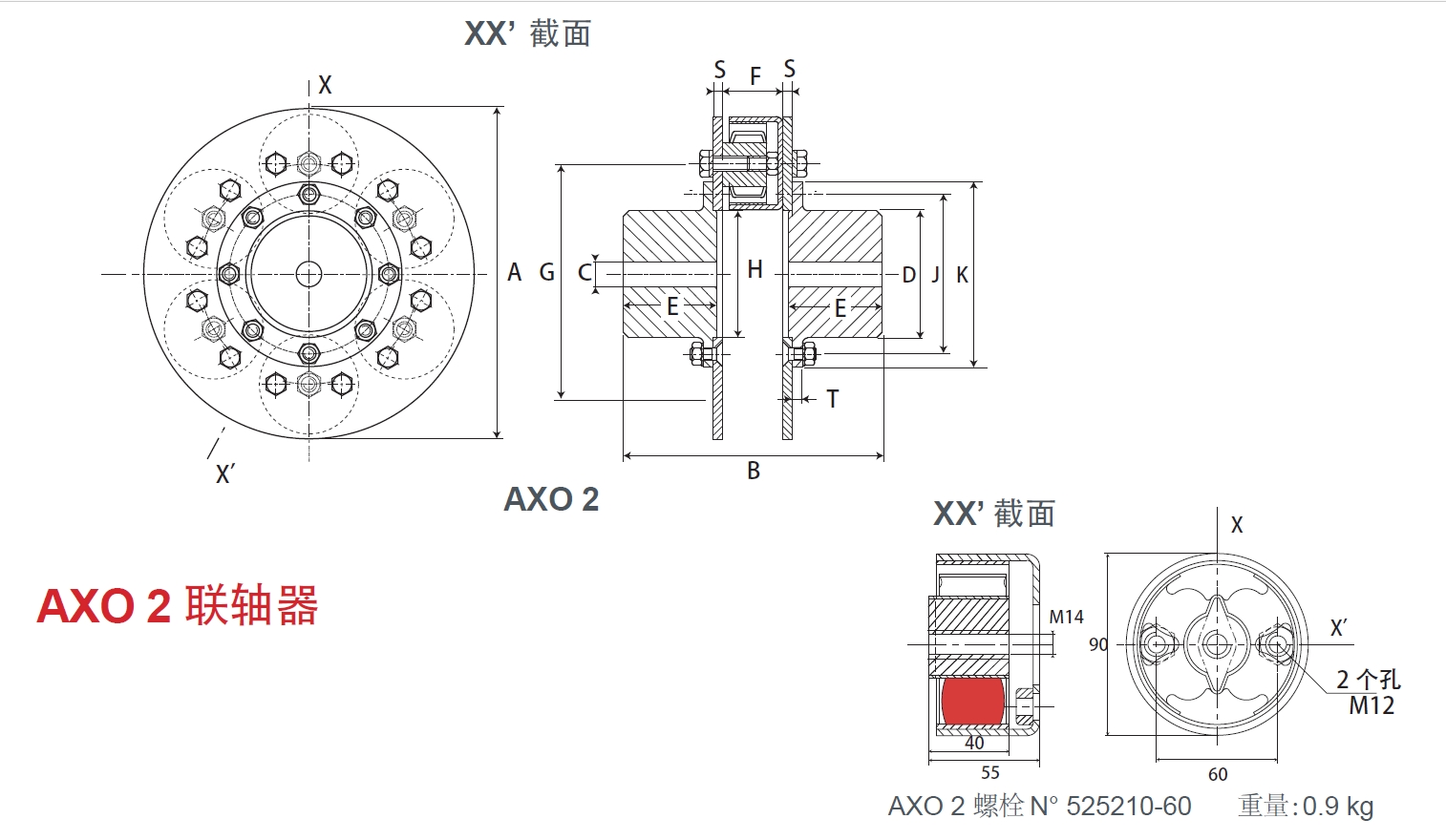

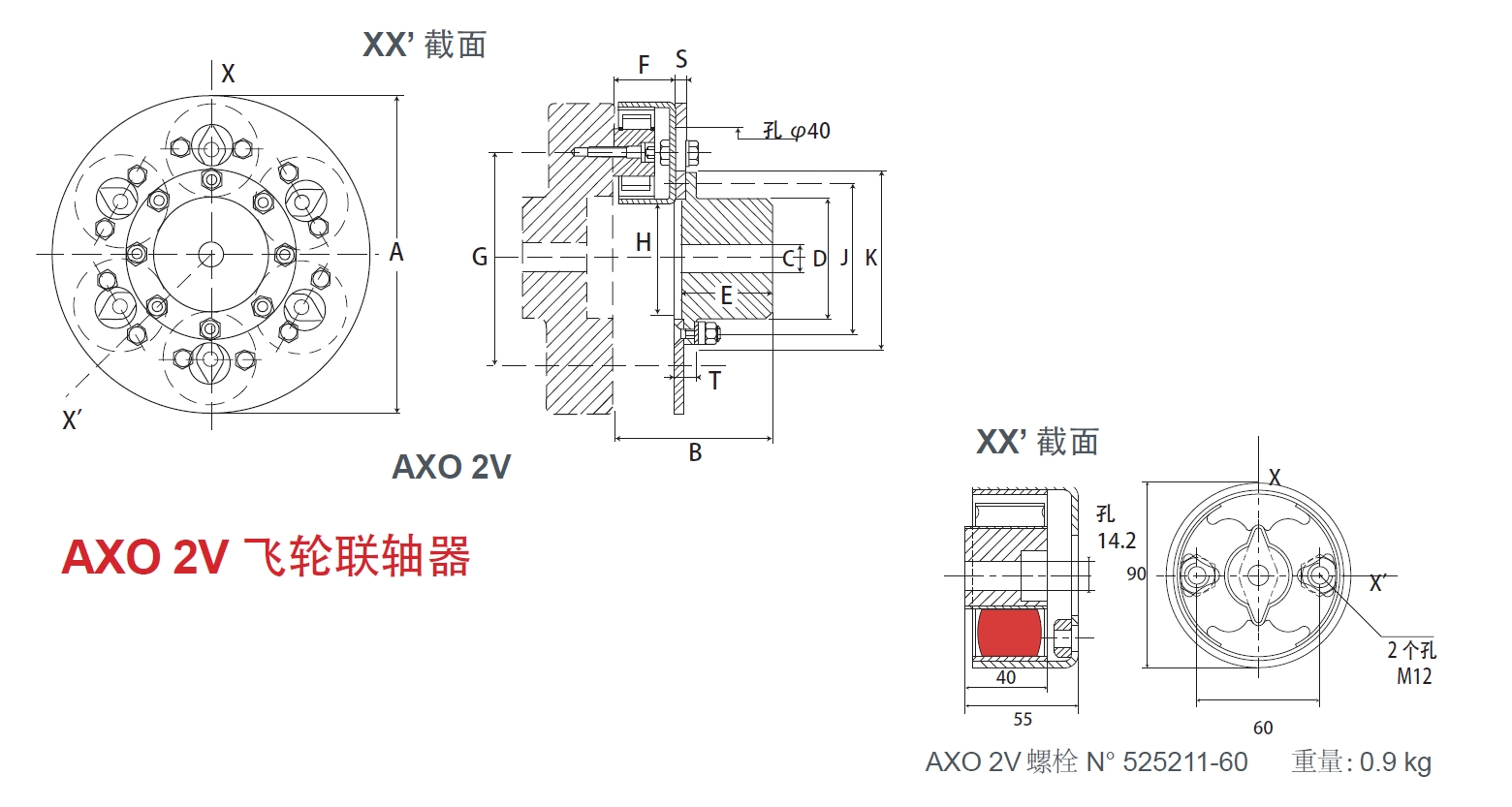

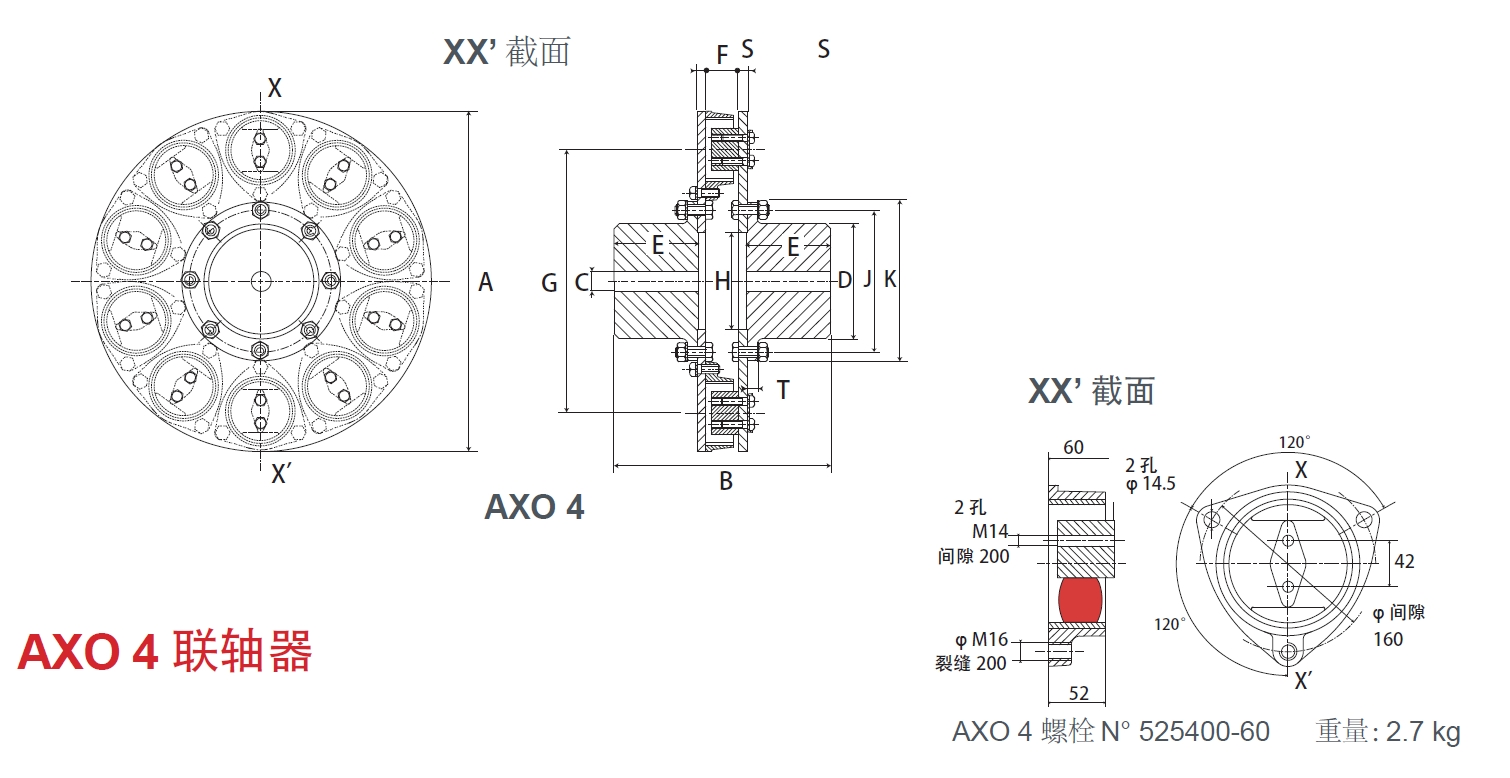

➤Steel disks Flange to which the inner studs are attached (normal mounting). Disk to which the studs are attached (flywheel mounting).➤ Die cast steel hubs The two hubs are identical. They may be bolted to disks or depending on the mountingused.

-

Elastic coupling - Axoflex Advantage +

The AXOFLEX coupling is designed with the following features :➤ radial disassembly without moving the machines that are coupled (usually very large machines);➤ precompression of the rubber which limits operation under tension.

Advantage➤ Good axial flexibility which allows great axial displacement, for example in the case of conical rotormachines. -

Elastic coupling - Axoflex Performance +

运行限制

径向偏离

额定扭矩

N.m轴向位移

转速为1500rpm600

800

1300

2300

3600

5000

7500

12000

175002 rpm

2 rpm

2 rpm

2 rpm

2 rpm

3 rpm

3 rpm

3 rpm

3 rpm

运行特征 AXO 2额定扭矩

N.m振动耦合

N.m加速工况下的扭转角度

(角度)刚度 轴向

daN/mm径向

daN/mm扭矩

m.KN600 300 3° 30′ 22 75 10.9 800 400 3° 30′ 30 100 14.3 1300 650 3° 45 150 25.8 2300 1150 2° 30′ 60 210 53.3 3600 1800 2° 75 250 114.6 5000 2500 1° 50′ 90 300 190 1 N.m ≈ 0.1 mkg

运行特征 AXO 4额定扭矩

N.m振动耦合

N.m加速工况下的扭转角度

(角度)刚度 轴向

daN/mm径向

daN/mm扭矩

m.KN5000 2500 1° 50′ 100 360 157 8000 4000 1° 40′ 130 480 252 12000 6000 1° 20′ 170 600 528 17500 8750 1° 200 720 916 24000 12000 0° 50′ 240 850 1550 40000 20000 0° 40′ 300 1100 3300 1 N.m ≈ 0.1 mkg

-

Elastic coupling - Axoflex Specifications +

尺寸

额定扭矩

N.m最大扭矩

N.m最大转速

rpm孔径C

mmA

mmB mm

类型D

mmE

mm标准联轴器

产品型号飞轮联轴器 F

mmG

mmH

mmJ

mmK

mmS

mmT

mm重量

kgmin max stan. flyw. 600 1200 3000 18 60 270 181 138 86 60 615253 615253 55 180 85 115 138 6 7 14 800 1600 3000 18 60 270 181 138 86 60 615354 615254 55 180 85 115 138 6 7 15 1300 2600 3000 23 80 300 235 145 115 85 615206 615256 55 200 115 145 168 8 9.5 28 2300 4600 2500 23 80 364 235 145 115 85 615208 615258 55 268 115 145 168 8 9.5 45 3600 7200 2500 28 100 424 274 164 145 102 615210 615260 55 324 145 180 210 10 12.5 72 5000 10000 2000 28 120 475 345 200 177 136 615212 615262 55 380 178 213 247 12 16 103

额定扭矩

N.m最大扭矩

N.m最大转速

rpm孔径C

mmA

mmB mm

类型D

mmE

mm标准联轴器

产品型号飞轮联轴器 F

mmG

mmH

mmJ

mmK

mmS

mmT

mm重量

kgmin max stan. flyw. 5000 10000 1800 28 100 480 279 170 145 102 615406 615456 60 340 145 180 210 10 12.5 80 7500 15000 1800 28 120 513 346 203 177 136 615408 615458 60 373 178 213 247 10 16 115 12000 24000 1500 28 120 622 358 209 177 136 615410 615460 06 482 178 213 247 16 16 178 12000 24000 1500 32 150 622 396 228 210 155 615440 615490 60 482 178 260 290 16 18 200 17500 35000 1500 32 150 720 396 228 210 155 615414 615462 60 580 178 260 290 16 18 240 17500 35000 1500 36 170 720 516 288 240 215 615442 615492 60 580 240 290 335 16 24 300 24000 1400 36 170 840 524 292 240 215 615414 615464 60 700 240 290 335 20 24 400 24000 1400 36 200 840 570 315 285 240 615444 615494 60 700 240 335 380 20 40 500 40000 1200 36 200 1040 590 325 285 240 615418 615468 620 900 240 335 380 30 40 700 ASSEMBLYMethod : (normal) :- attach each of the flanges to the ends of the appropriate shafts;

- use the specially machined recess to centre the disks onto the flanges and screw together;

- attach the external armature of the studs to the appropriate disk;

-

attach the internal armature of the studs to the other disk.

Torque for the bolts attaching the studs.Ø 12 ⇒75 N.m

Ø 14 ⇒122 N.m

Ø 16 ⇒185 N.m

Method : (flywheel) :- mount the flange onto the shaft end;

- bolt the disk onto the flange;

- attach the external armature of the studs to the disk;

- attach the internal armature of the studs to the flywheel of the second machine.

Chinese

Chinese English

English

Top

Top