Products

- Elastomer-metal vibration isolator

- Rubber-metal vibration isolator (support)

- Rubber-metal vibration isolator (foot pad)

- Rubber vibration isolator- S.C

- Rubber vibtation isolator - EV

- Rubber vibration isolator - PA

- Rubber vibration isolator - PA

- Rubber vibraton isolator- &quo

- Rubber vibration isolator- CUP

- Rubber vibration isolator -STA

- Rubber vibration isolator bear

- Engine unit vibration isolator

- Rubber vibration isolator -MIN

- Rubber vibration isolator - BE

- Rubber vibration isolator- POL

- Rubber-metal vibration isolator (suspension)

- Rubber-metal vibration isolator (military)

- Rubber vibration isolator- ST

- Rubber vibration isolator- VI

- Rubber vibration isolator- VI

- Rubber vibration isolator- &qu

- Rubber vibration isolator - GB

- Rubber vibration isolator - VI

- Rubber vibration isolator - VI

- Rubber vibration isolator- VIB

- Rubber vibration isolator- VII

- Rubber vibration isolator - lo

- Rubber vibration isolator - VI

- Silicone damping vibration isolator

- Elastomer spring

- Mechanical equipment vibration isolation pad foot

- Steel spring assembly vibration isolator

- Small steel spring set vibration isolator

- Large steel spring set vibration isolator

- S-WLP steel spring vibration i

- S-ULP steel spring vibration i

- S-ULP steel spring vibration i

- S-WP (R) steel spring vibratio

- S-WP steel spring vibration is

- S-WPV steel spring vibration i

- S-WPV (R) steel spring vibrati

- S-WLP steel spring vibration i

- S-WLP steel spring vibration i

- S-WLP steel spring vibration i

- S-WLP steel spring vibration i

- S-WLP steel spring vibration i

- Steel spring-viscous damping vibration isolator

- Steel spring vibration isolator

- Damping vibration isolator

- Air spring vibration isolator

- Metal wire, vibration isolator

- Steel wire rope vibration isolator

- Metal wire vibration isolator

- Metal wire vibration isolators

- Metal wire vibration isolator

- Metal wire vibration isolators

- Metal wire vibration isolator

- Metal wire vibration isolator

- Metal wire vibration isolator

- Metal wire vibration isolator-

- Metal wire vibration isolator

- Metal wire vibration isolator

- Metal wire vibration isolator

- Wire rope vibration isolator -

- Metal wire vibration isolator

- HVAC vibration isolator

- Hanging vibration isolator

- Floating floor vibration isolator

- HVAC vibration isolator

- DZE 3D damping vibration isola

- MSN-D damping vibration isolat

- COMPACT damping vibration isol

- DZE damping vibration isolator

- DZE-MINI damping vibration iso

- DZE-BL damping vibration isola

- SE light series vibration isol

- SE-DE series traction machine

- ENI leveling vibration-isolati

- CGR vibration isolator

- EW vibration isolator gasket

- TR Transformer vibration isola

- PBE vibration isolator pad

- SE Pro series vibration isolat

- Active vibration isolation system

- Anti-vibration base

- Polyurethane elastomer vibration isolation material

- RELOMER SRG60 vibration isolat

- RELOMER SRG35 vibration isolat

- RELOMER SRG14 vibration isolat

- RELOMER SRG08 vibration isolat

- ACOUSTIC FLOOR MAT 35

- ACOUSTIC FLOOR MAT 33

- ACOUSTIC FLOOR MAT 29

- ROLL acoustic floor mat

- Sylocraft vibration isolation

- Sylodyn high dynamic vibration

- Sylomer elastic vibration isol

- Sylodamp damping and vibration

首页 > Products > Elastomer-metal vibration isolator > Coupling vibration isolator

Elastic Coupling Radiaflex RTP

-

Elastic Coupling Radiaflex RTP Overview -

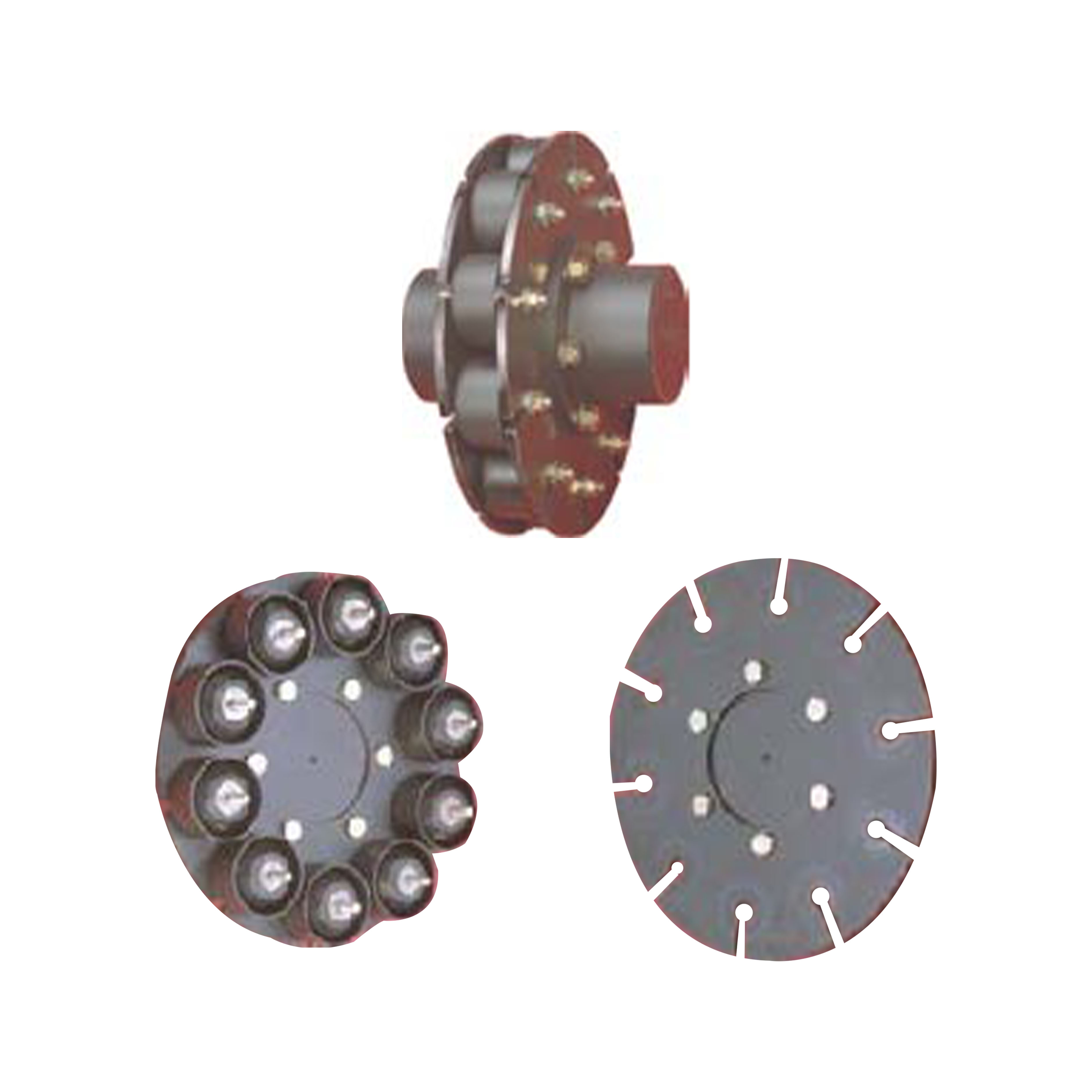

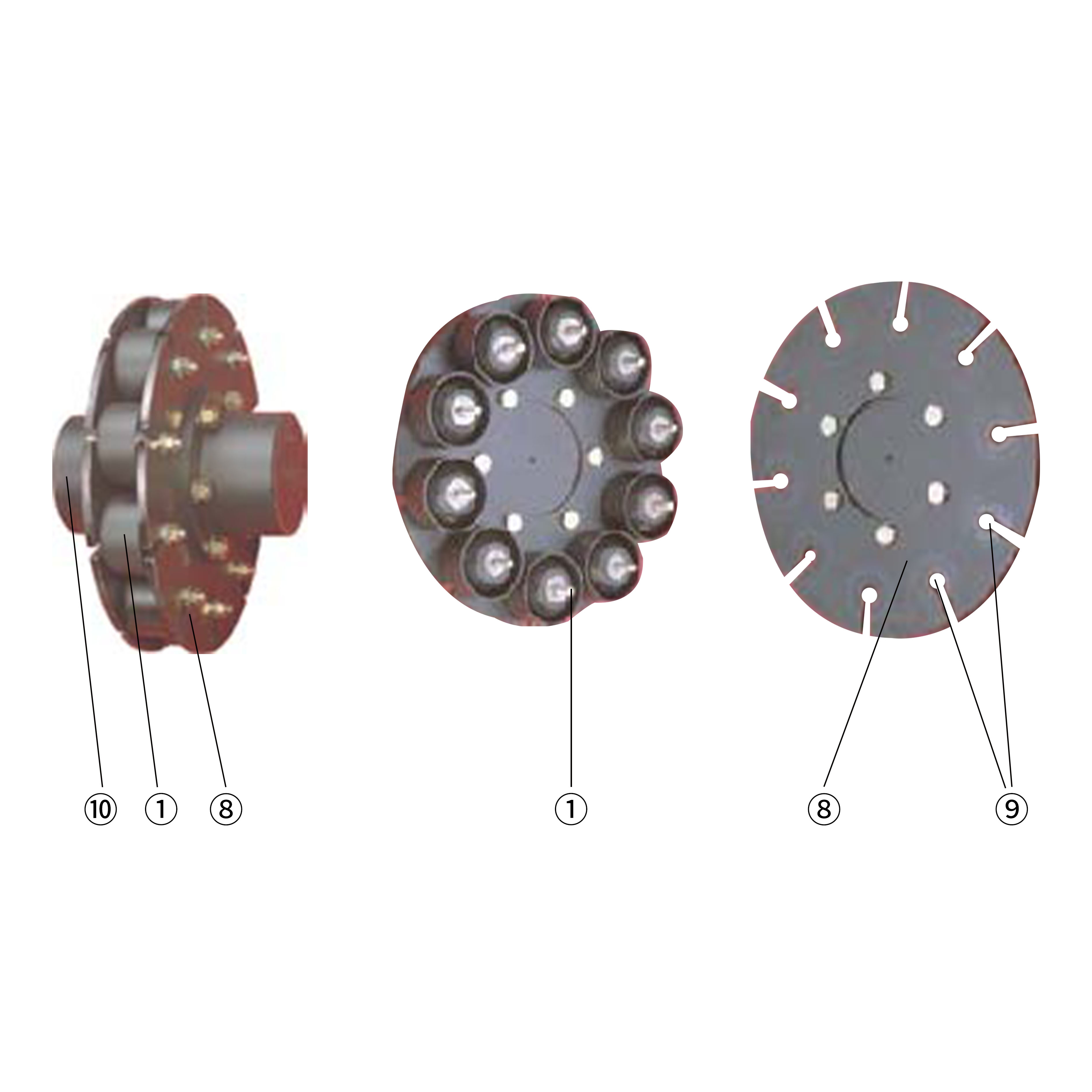

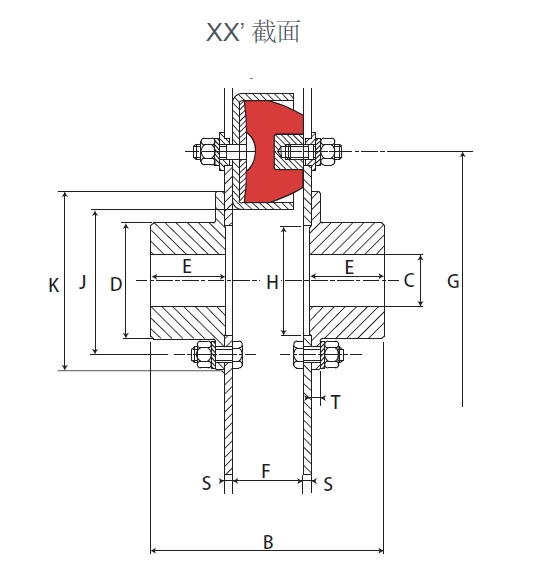

➤Flexible element made up of a variable number of flexible studs- depending on the torque to be transmitted.

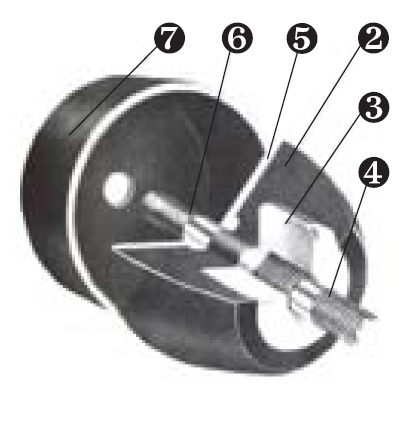

- Solid natural rubber blocks in the form of a truncated cone.

- Internal armature bonded to the rubber.

- Threaded stud.

- External armature bonded to the rubber.

- Studding welded to armature.

- Cylindrical metal cover.

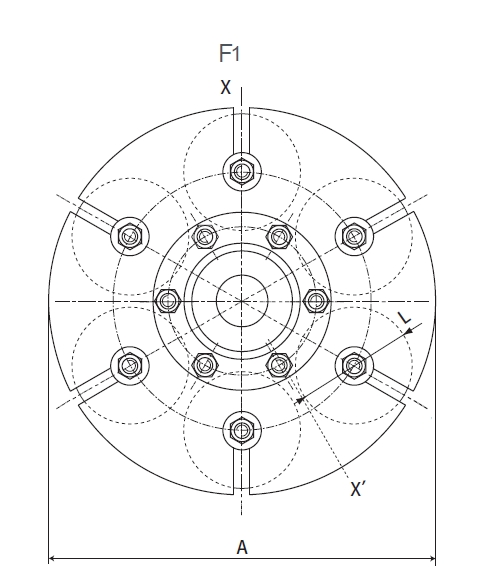

➤Steel disks Two identical disks, bolted to the flanges and with slits to housethe studs .➤Flanges die-cast steel.

-

Elastic Coupling Radiaflex RTP Advantage +

The RADIAFLEX RTP coupling is designed with the following features :➤ the studs can be removed radially without moving the coupled machines;➤ at low and average torque : the rubber operates under compression;➤ at high torque : there is progressive thrust of the rubber against the metal cover ; .safe in use;➤ it can absorb the effects of tension or compression axially (for example: push andpull of a helical screw). -

Elastic Coupling Radiaflex RTP Performance +

-

Elastic Coupling Radiaflex RTP Specifications +

Size

产品型号

额定扭矩

N.mm最大扭矩

N.mm最大转速

rpm孔径C A

mmB

mmD

mmE

mm类型 产品型号 F

mmG

mmH

mmJ

mmK

mmL

mmS

mmT

mm重量

kgmin max 470 1000 3000 18 60 270 181 86 60 RTP 2.3 612203 55 180 85 115 138 90 6 7 13 630 1250 3000 18 60 270 181 86 60 RTP 2.4 612204 55 180 85 115 138 90 6 7 15 1100 2200 3000 18 60 300 185 86 60 RTP 2.6 612206 55 200 85 115 138 90 8 7 28 1800 3600 2500 23 80 364 235 115 85 RTP 2.8 612208 55 264 115 145 168 90 8 9.5 45 2500 5000 1500 28 100 420 299 145 102 RTP 4.6 612210 80 280 145 180 210 130 10 12.5 77 2800 5600 2500 28 100 424 274 145 102 RTP 2.10 612212 55 324 145 180 210 90 10 12.5 72 4100 8200 2000 28 120 475 345 177 136 RTP 2.12 612408 55 380 178 213 247 90 12 16 103 4500 9000 1500 28 120 510 370 177 136 RTP 4.8 612410 80 370 178 213 247 130 12 16 127 6900 13500 1500 28 120 600 382 177 136 RTP 4.10 612412 80 460 178 213 247 130 18 16 178 9700 20000 32 150 680 424 210 155 RTP 4.12 612412 80 540 178 260 290 130 20 18 253 17500 35000 32 150 860 424 210 155 RTP 4.16 612416 80 720 178 260 290 130 20 18 330 17500 35000 32 155 826 687 220 250 RTP 6.6 612606 147 580 200 246 30 590 34000 68000 32 220 1096 827 320 320 RTP 6.8 612608 147 850 320 246 30 1140 60000 120000 32 200 1246 827 320 320 RTP 6.12 612612 147 1000 250 246 30 1200 72000 140000 32 360 1446 827 320 320 RTP 6.12 612613 147 1200 500 246 30 2200 104000 200000 35 360 1546 889 350 350 RTP 6.16 612616 147 1300 500 246 30 2500

运行参数

额定扭矩

N.m振动耦合

N.m加速工况下的扭转角度

(角度)轴向压缩

daN/mm轴向压缩

daN/mm轴向拉伸

daN/mm扭力

m.KN/rad锥向扭力

m.KN/rad470 235 3° 10′ 375 300 105 8.6 10.3 630 345 3° 10′ 500 400 140 11.4 20.6 1100 550 2° 50′ 750 600 210 21.2 86 1800 900 2° 10′ 1000 800 280 49.3 114 2500 1250 2° 15′ 1500 1200 330 65.5 86 2800 1400 1° 50′ 1250 1000 350 92.6 229 4100 2050 1° 30′ 1500 1200 420 160 573 4500 2250 1° 40′ 2000 1600 440 152 460 6900 3450 1° 25′ 2500 2000 550 292 1030 9700 4850 1° 10′ 3000 2400 660 482 17500 750 0° 50′ 4000 3200 880 1140 17500 8750 2° 10′ 3000 1800 550 458 34000 17000 1° 30′ 4000 2400 730 1320 60000 30000 1° 15′ 6000 3600 1100 2700 72000 36000 1° 6000 3600 1100 3900 104000 52000 0° 50′ 8000 4800 1460 6100

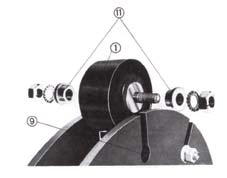

ASSEMBLYMethod :- mount each of the flanges onto the ends of the corresponding shafts;

- use the specially machined recess to centre the disks onto the flanges and screw together;

- attach the external armature of the studs to the appropriate disk;

- attach the internal armature of the studs to the other disk.

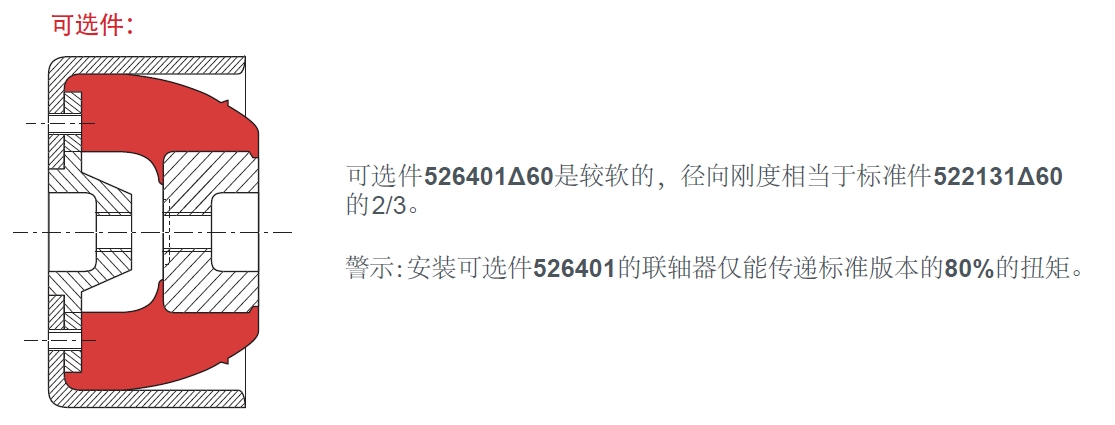

Note :The slits are designed to take the loose locating sleeves 11 to enable the individual flexible studsto be mounted and removed radially.

Note :The slits are designed to take the loose locating sleeves 11 to enable the individual flexible studsto be mounted and removed radially.

Torque to be applied to the stud fixing bolts :- Stud RTP2 : 522090 Ø 12⇒ 75 N.m.

- Stud RTP4 : 522131 Ø 16⇒ 185 N.m.

- Stud RTP6 : 522240 Ø 24 ⇒ 640 N.m.

Chinese

Chinese English

English

Top

Top