Products

- Elastomer-metal vibration isolator

- Rubber-metal vibration isolator (support)

- Rubber-metal vibration isolator (foot pad)

- Rubber vibration isolator- S.C

- Rubber vibtation isolator - EV

- Rubber vibration isolator - PA

- Rubber vibration isolator - PA

- Rubber vibraton isolator- &quo

- Rubber vibration isolator- CUP

- Rubber vibration isolator -STA

- Rubber vibration isolator bear

- Engine unit vibration isolator

- Rubber vibration isolator -MIN

- Rubber vibration isolator - BE

- Rubber vibration isolator- POL

- Rubber-metal vibration isolator (suspension)

- Rubber-metal vibration isolator (military)

- Rubber vibration isolator- ST

- Rubber vibration isolator- VI

- Rubber vibration isolator- VI

- Rubber vibration isolator- &qu

- Rubber vibration isolator - GB

- Rubber vibration isolator - VI

- Rubber vibration isolator - VI

- Rubber vibration isolator- VIB

- Rubber vibration isolator- VII

- Rubber vibration isolator - lo

- Rubber vibration isolator - VI

- Silicone damping vibration isolator

- Elastomer spring

- Mechanical equipment vibration isolation pad foot

- Steel spring assembly vibration isolator

- Small steel spring set vibration isolator

- Large steel spring set vibration isolator

- S-WLP steel spring vibration i

- S-ULP steel spring vibration i

- S-ULP steel spring vibration i

- S-WP (R) steel spring vibratio

- S-WP steel spring vibration is

- S-WPV steel spring vibration i

- S-WPV (R) steel spring vibrati

- S-WLP steel spring vibration i

- S-WLP steel spring vibration i

- S-WLP steel spring vibration i

- S-WLP steel spring vibration i

- S-WLP steel spring vibration i

- Steel spring-viscous damping vibration isolator

- Steel spring vibration isolator

- Damping vibration isolator

- Air spring vibration isolator

- Metal wire, vibration isolator

- Steel wire rope vibration isolator

- Metal wire vibration isolator

- Metal wire vibration isolators

- Metal wire vibration isolator

- Metal wire vibration isolators

- Metal wire vibration isolator

- Metal wire vibration isolator

- Metal wire vibration isolator

- Metal wire vibration isolator-

- Metal wire vibration isolator

- Metal wire vibration isolator

- Metal wire vibration isolator

- Wire rope vibration isolator -

- Metal wire vibration isolator

- HVAC vibration isolator

- Hanging vibration isolator

- Floating floor vibration isolator

- HVAC vibration isolator

- DZE 3D damping vibration isola

- MSN-D damping vibration isolat

- COMPACT damping vibration isol

- DZE damping vibration isolator

- DZE-MINI damping vibration iso

- DZE-BL damping vibration isola

- SE light series vibration isol

- SE-DE series traction machine

- ENI leveling vibration-isolati

- CGR vibration isolator

- EW vibration isolator gasket

- TR Transformer vibration isola

- PBE vibration isolator pad

- SE Pro series vibration isolat

- Active vibration isolation system

- Anti-vibration base

- Polyurethane elastomer vibration isolation material

- RELOMER SRG60 vibration isolat

- RELOMER SRG35 vibration isolat

- RELOMER SRG14 vibration isolat

- RELOMER SRG08 vibration isolat

- ACOUSTIC FLOOR MAT 35

- ACOUSTIC FLOOR MAT 33

- ACOUSTIC FLOOR MAT 29

- ROLL acoustic floor mat

- Sylocraft vibration isolation

- Sylodyn high dynamic vibration

- Sylomer elastic vibration isol

- Sylodamp damping and vibration

S-ULP-V steel spring (viscous damping) vibration isolator S-ULPV-2011.../47

减震器/钢弹簧(粘滞阻尼)减震器.jpg)

-

S-ULP-V steel spring (viscous damping) vibration isolator S-ULPV-2011.../47的概况 -

Spring elements are effectively used for mechanical vibration isolation in power plants. Turbine worktable, feedwater pump, etc. They provide support for static loads and reduce the transmission of dynamic loads to the foundation.Application Description:➤ Elastic foundation of steam turbine➤ Elastic foundation of steam turbine unit➤ Elastic foundation of coal mill➤ Elastic foundation of fan➤ Install the blower and condenser -

S-ULP-V steel spring (viscous damping) vibration isolator S-ULPV-2011.../47的优势 +

Spring elements are effectively used for mechanical vibration isolation in power plants. Turbine worktable, feedwater pump, etc. They provide support for static loads and reduce the transmission of dynamic loads to the foundation. Spring components typically consist of three main parts: upper and lower shells, spiral coil springs, and viscoelastic dampers. The system frequency is usually between 2-7 Hz.The basic design of the spring element consists of a set of spiral coil steel compression springs connected to the top and bottom plates. In general, due to the natural material damping of steel components, the damping performance of spring elements is very low. As long as higher damping characteristics are required, viscoelastic damping elements can be integrated into spring elements. An important feature of spring elements is their ability to lock them at a predetermined compression level (preload). Pre installed spring elements are installed in the locked position to serve as solid supports. At the end of installation - possibly heavy machinery - the spring elements are activated: they are unlocked. From that moment on, the device acted as a vibration control component. -

S-ULP-V steel spring (viscous damping) vibration isolator S-ULPV-2011.../47的性能 +

This product portfolio covers most typical applications of basic isolation in power plants and installation of condensers. By combining a set of spring elements in one application, optimal settings can be achieved. The spring element is independent of the additional damping element. Without damping, the load covered by the component ranges from 126kN to 2096kN, with a damping load of up to 1300kN. -

S-ULP-V steel spring (viscous damping) vibration isolator S-ULPV-2011.../47的指标 +

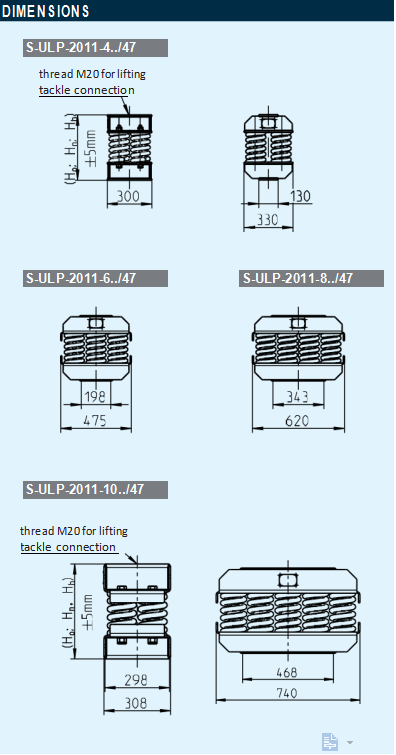

Basic parameters required for design selection:➤ Load [kN], determined by the weight and load distribution of the supporting machine➤ Main excitation frequency of vibration source [Hz]➤ Operating temperature [° C] - in the case of damping elements➤ Installation size [mm] and geometric limitationsH0: unloaded height

Hn: height at nominal load

Hb: height at blockload Spring element type: S-ULPV-2011./47

Spring element type: S-ULPV-2011./47S-ULPV-2011

Model

Nom.load

[kN]

Vert.stiffness

[kN/mm]

Hor.stiffness

[kN/mm]

Height

[mm]

Damping parameter

[kNs/m]

H0

Hn

Hb

dv

dh

S-ULPV-2011-4.0/47

127

2.71

2.08

440

393

377

85

170

S-ULPV-2011-4.1/47

137

2.92

2.10

S-ULPV-2011-4.2/47

146

3.12

2.12

S-ULPV-2011-4.3/47

156

3.33

2.14

S-ULPV-2011-4.4/47

165

3.53

2.16

S-ULPV-2011-6.0/47

191

4.07

3.12

S-ULPV-2011-6.1/47

200

4.27

3.14

S-ULPV-2011-6.2/47

210

4.48

3.16

S-ULPV-2011-6.3/47

219

4.68

3.18

S-ULPV-2011-6.4/47

229

4.89

3.20

S-ULPV-2011-6.5/47

239

5.09

3.22

S-ULPV-2011-6.6/47

248

5.29

3.24

Max. weight approx:141 kg

S-ULPV-2011-8.0/47

254

5.42

4.16

440

393

377

110

230

S-ULPV-2011-8.1/47

264

5.63

4.18

S-ULPV-2011-8.2/47

274

5.83

4.20

S-ULPV-2011-8.3/47

283

6.04

4.22

S-ULPV-2011-8.4/47

293

6.24

4.24

S-ULPV-2011-8.5/47

302

6.45

4.26

S-ULPV-2011-8.6/47

312

6.65

4.28

S-ULPV-2011-8.7/47

322

6.85

4.30

S-ULPV-2011-8.8/47

331

7.06

4.31

Max. weight approx:162 kg

S-ULPV-2011-10.0/47

318

6.78

5.20

440

393

377

140

300

S-ULPV-2011-10.1/47

328

6.98

5.22

S-ULPV-2011-10.2/47

337

7.19

5.24

S-ULPV-2011-10.3/47

347

7.39

5.26

S-ULPV-2011-10.4/47

356

7.60

5.28

S-ULPV-2011-10.5/47

366

7.80

5.30

S-ULPV-2011-10.6/47

376

8.01

5.32

S-ULPV-2011-10.7/47

385

8.21

5.34

S-ULPV-2011-10.8/47

395

8.42

5.36

S-ULPV-2011-10.9/47

405

8.62

5.37

S-ULPV-2011-10.10/47

414

8.82

5.39

Max. weight approx: 210 kg

(*) heights and weights exclude allowances for adhesive pads and shims

REMARKS:1) calculated according to DIN EN 13906-12) natural frequency at nominal load 2.3 Hz3) spring elements are fully prestressable4) 2x4mm adhesive pads and shims on request5) dv; dh: min. values are given for height Hn at natural frequencies fv; fh at 20°C

中文

中文 英文

英文

Top

Top